Cruise Ship Water Filtration

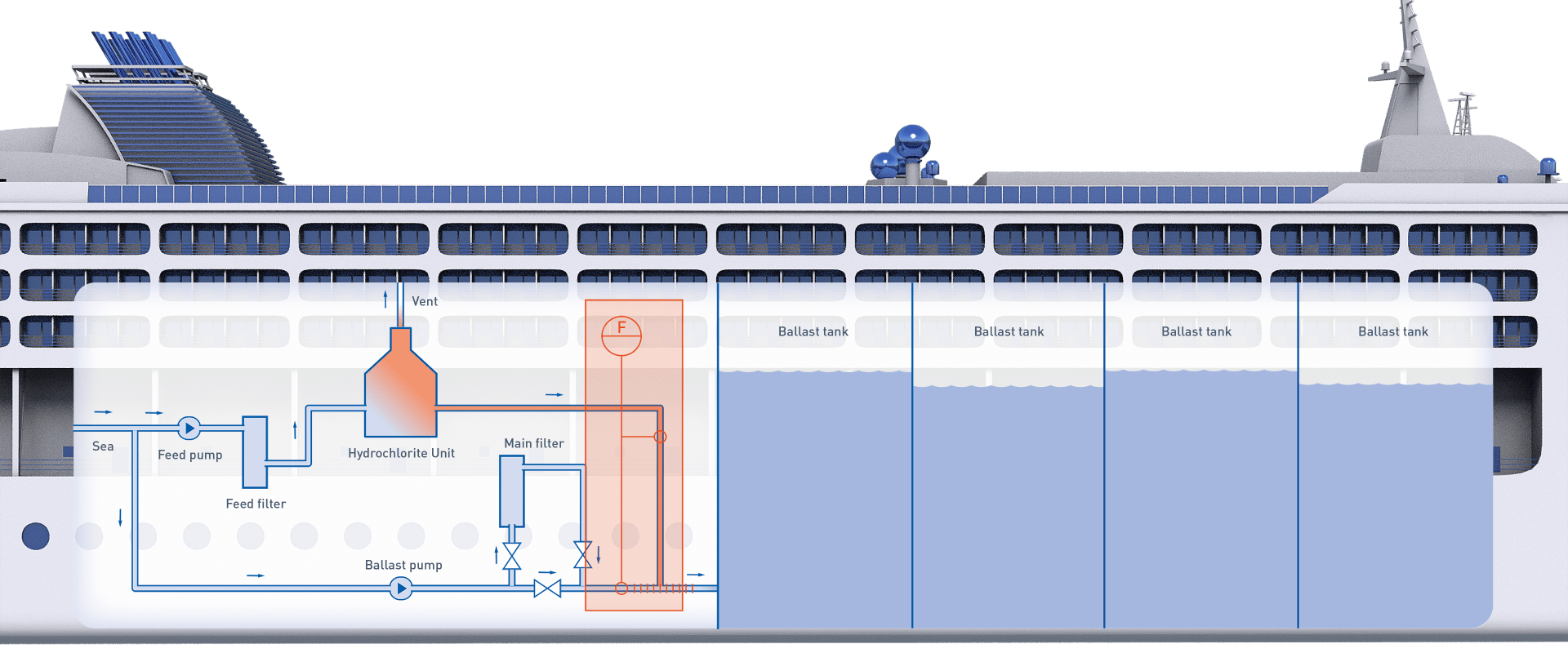

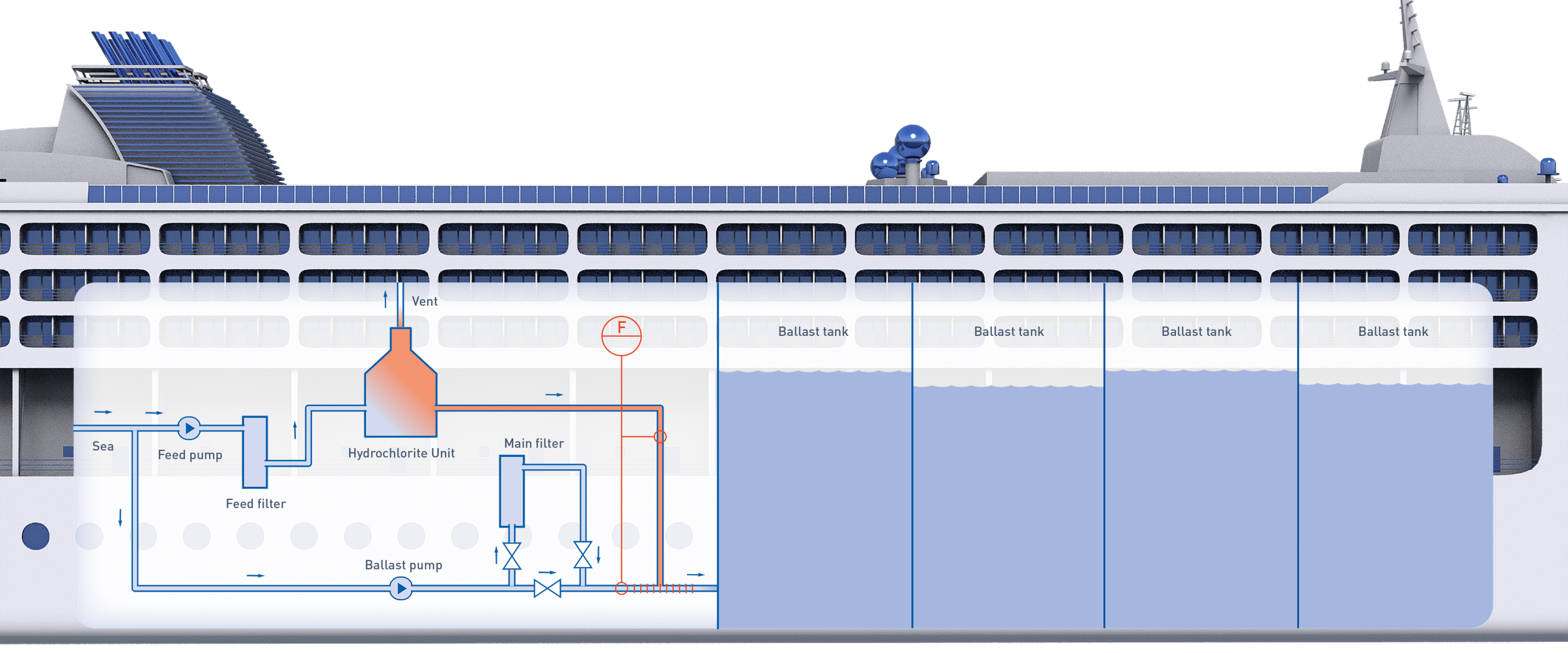

The water is sent into a filtration system to separate solids.

Cruise ship water filtration. Ad PURELAB MEDICA CENTRA with our PURESURE water filtration technology. Initially saltwater from the sea enters the desalination system and passes through an optional 100 micron strainer designed to remove any large contaminants such as seaweed or fish into a low pressure boost pump. You pay a base fee to go on a cruise.

Filtration Process B. After desalination the water is passed through a mineralization plant which adds minerals. Instead of lugging water on board or paying extra for it on the ship filter it - and the filter will work perfectly well at.

Blackwater requires treatment before discharge whereas the greywater can be discharged directly into the sea with minimal filtration. A ship of 2200 passengers and 900 crew will use about 800-1000 metric tons 200000-260000 gallons of water per day so cost effective. As liveaboard cruisers ourselves we work hard to provide fellow cruisers with affordable cruiser tested solutions for their Water Maker Power Generating and Marine Refrigeration needs.

They do this with a desalination plant either using multi effect distillation or. Culligan water treatment systems are operating on many of the most prestigious cruise liners across the world. What is the water filtration process on a cruise ship.

This feed water is then boosted to approximately 1 bar through a sediment pre-filter. To elaborate on Tom Mcfarlanes amswer. The liquid is sent into a bioreactor and membrane filtration system to further filter impurities.

All modern cruise ships distill water. In a method that mimics nature where evaporated sea water falls as rain the onboard system uses osmosis which uses a fine membrane to filter sea water separating minerals and salt. After desalination the water is passed through a mineralization plant which adds minerals.